3D Printing Expands The Reach Of Digital Disruption

2013 was a year in which media attention and hype targeted 3D printing: “artisanal” do-it-yourself (DIY) upstarts on Kickstarter making headlines across the blogosphere every week; high-profile speculation, such as President Obama’s quip that 3D printing will create a new manufacturing economy in the US; and Victoria's Secret models strutting down the runway in elaborate 3D printed corsets and signature wing accessories.

The excitement has reached the C-suite, where execs are wondering how this elusive and unfamiliar new technology will affect their business. As the resident techie, the CIO should expect the questions to come her way: What are the business implications? How fast is the technology developing? What are the implications for business technology at your organization?

Over the past six months, my colleague Sophia Vargas and I have been working to understand the trajectory of 3D printing and its impact on business and technology. Clients can read our newly released Forrester report 3D Printing Drives Digitization Further Into Products, Processes, And Delivery Models for our full analysis.

Here are three angles on how 3D printing is driving business impact and digital disruption:

1. 3D printing can create tremendous business value — today. 3D printing enables key business imperatives in the age of the customer: faster time to market, new products and new markets, and the expansion of personalized products or services.

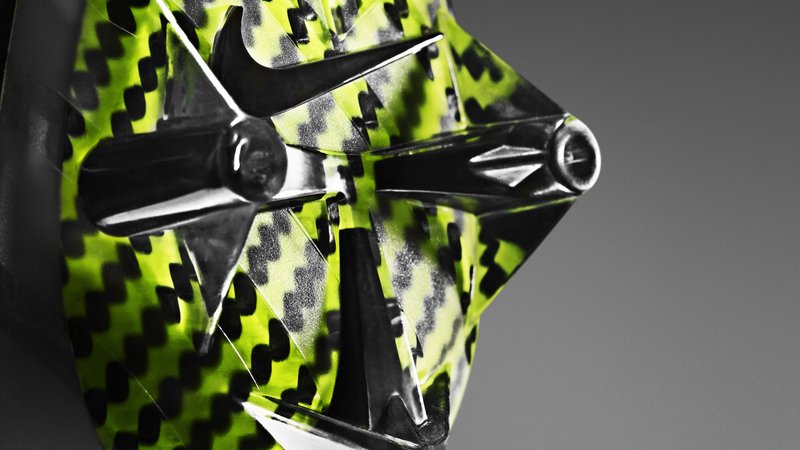

For those of you who tuned into the Super Bowl recently, players for both the Broncos and Seahawks wore custom-made Nike cleats prototyped and manufactured on 3D printers, most likely from 3D Systems. Nike leveraged the geometric precision of 3D printing to minimize the friction on the field that slows athletes down, and it streamlined the prototyping and manufacturing of a small batch of finished products from years to months.

[Image courtesy of Nike.com]

2. 3D printing expands the reach of digital disruption.The end-to-end digital process of 3D printing reshapes elements of production and the role of business technology. Specifically, it:

- Enables flexibility and transformation in the early stages of the product sequence. 3D printing makes it easier and faster to change features on the fly, giving much greater flexibility to the supply chain within a factory or across a continent; changes in components and subassemblies can be made at the speed of the Internet.

- Drives digitization much deeper into manufacturing, creating greater visibility and control. While manufacturing processes are traditionally monitored using sensors and automation, 3D print processes are natively digital, with every element under the continuous control of software. Look for developments such as embedded digital serial numbers in every part, full part history and traceability, and a recentralization of manufacturing supply chains as labor costs become less of a factor for factory location.

3. 3D printing, when coupled with the Internet of Things and digital data platforms, disrupts entire value chains. How? It’s the underpinnings of a truely “software-driven” business model, in which every aspect of a physical product — from creation to delivery — is digitally controlled. As a crude and early example, SOLS aims to disrupt orthotics with a digital service for custom shoe insoles. A customer's feet are scanned with a smartphone video camera, and the scan is rendered into a 3D model. Contextual data such as weight, lifestyle, and activity patterns are factored into the specifications before a custom insole is sent to print. Business models that eliminate analog layers and constituents, and blur the lies between physical processes and native digital control will have huge impact. For a sense of the magnitude, eyewear innovator Warby Parker — which disrupts only parts of the eyewear value chain — is valued at $500 million. We’re keeping tabs on PTC’s acquisition of ThingWorx, a digital platform for the Internet of Things, as it couples with core product life-cycle management and 3D modeling software suites to enable “software-driven” business models.

What should CIOs do today? The CIO should use her technology expertise to gain relevance as a business enabler in driving digital disruption.

Start by assigning a liaison to manufacturing and engineering groups to better understand the business' innovative practices and requirements. If you don’t, these groups will silo technology management, just as factories once did. For more on the new responsibilities that CIOs must take on to meet the rising demands for infrastructure, expertise, and support, read Sophia’s blog.

PS — special thanks to superstar Forrester analysts Frank Gillett, Rachel Dines, and J.P. Gownder for guiding us and contributing to this piece of research.

Michael Yamnitsky is a researcher at Forrester Research. You can follow him on Twitter @ItsYamnitsky.