Industry 5.0? No Thanks!

Industry 4.0 has been a big idea in manufacturing for the past decade or so, but moves are unfortunately afoot to prematurely crown a successor: Industry 5.0. While the ever-shorter refresh cycles for smartphones have apparently become an unfortunate fact of consumerist life, industrial revolutions really should come along with a lot less frequency!

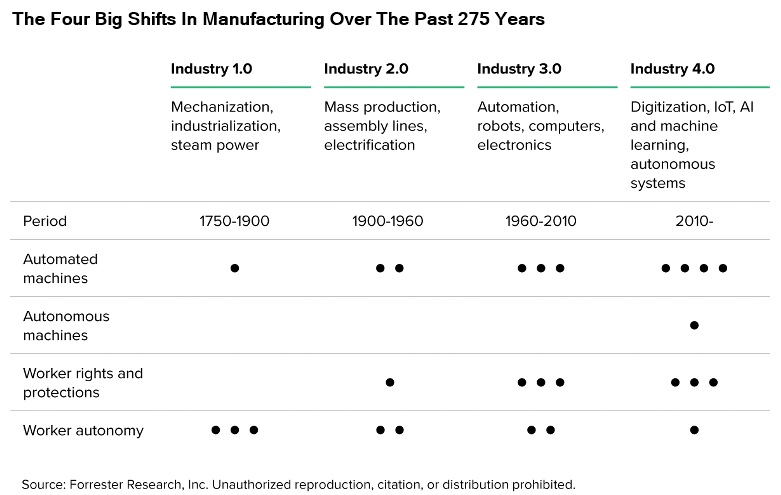

Industry 4.0 was born in Germany over a decade ago, first gaining broader attention at the Hannover Messe trade fair in 2011. Industry 4.0 (or the Fourth Industrial Revolution) is said to follow three earlier leaps in manufacturing technology, beginning with James Watt’s steam engine and the (first) Industrial Revolution that it unleashed back in the eighteenth century. My academic background in archaeology leads me to squirm uncomfortably at this, as I would argue that a lot of earlier innovations were also pretty revolutionary. Controlling fire, anyone? The harnessing of water power? The domestication of animals and crops that allowed early people to settle down and — eventually — specialise in things like making stuff? The deliberate smelting of copper, and then bronze, and then iron, and then steel? All sadly ignored in the neat narrative which says that “industry” was first “revolutionised” by Watt building steam-powered machines on the grounds of a big country house outside Edinburgh.

It may be too late to change the numbers by which we refer to undoubted technological advances over the past few centuries, but it’s not too late for me to beg that we slow down a little bit and think before adding even more numbers to the list.

- Industry 1.0 was a pretty big deal. James Watt and his contemporaries were the biggest thing to hit manufacturing since iron smelting arrived on the scene roughly 3,000 years ago. Steam power, industrial-scale weaving machines, cost-effective large-scale smelting of metals, and more triggered dramatic shifts in society, first off the fields and into industrial production, and then out of the countryside and into towns and cities. The progression from iron smelting to Watt’s steam engine took around 3,000 years. The next revolution arrived just 150 years later.

- Industry 2.0 broke the power of the artisan. Henry Ford and others brought standardisation and rigour to entire production processes, controlling cost and quality by ensuring that every product leaving a factory production line was essentially identical. Humans were still required to do all of the work, but their ability to be creative or different was gradually being suppressed in favour of efficiency, consistency, and cost control. Ford’s production lines arrived around 150 years after Watt’s steam engine. Just 60 years later, electronics changed things again.

- Industry 3.0 began to replace people’s muscles. General Motors installed the Unimate industrial robot on a New Jersey production line in 1961, and others were quick to follow. Robots took on a growing range of tasks, lifting, folding, banging, bending, or welding with greater consistency (and less injury) than the human workforce. Computers and other electronic systems told robots — and people — what to do and counted everything. Unimate began working in a New Jersey car plant 53 years after the first Model T Ford drove off a Michigan production line. Just 50 years later, data, sensors, and artificial intelligence changed things again.

- Industry 4.0 began to augment people’s brains. Germany, with its deep manufacturing heritage, was perhaps first to spot the potential for connecting industrial equipment to sensors in order to collect and analyse data to make processes more visible, more efficient, and (eventually) more sustainable and customer-centric. In specific circumstances, data, sensors, and physical automation (robots, etc.) combine to let entire processes run autonomously without direct human intervention. Cloud, connectivity, and affordable sensors made Industry 4.0 possible. Less than a decade later, some began hunting for a new revolution.

Industry 5.0 Describes Important Details Of Implementation, Not Another Revolution

SAP describes Industry 5.0 as human-centric, sustainable, and resilient. According to the European Commission, it “complements the existing Industry 4.0 approach by specifically putting research and innovation at the service of the transition to a sustainable, human-centric and resilient European industry.” Others make broadly similar claims. Few are going to argue against making resource-hungry manufacturing industries more sustainable. No one who lived through the past few years can seriously argue that going back to cost-optimised and brittle supply chains is a better idea than continuing to develop resilient supply networks. Good Industry 4.0 projects were always human-centric, placing the needs of the worker front and centre as they balanced the automation triangle.

There are plenty of Industry 4.0 projects that imposed robots or AI on a human workforce without properly considering the implications. There are plenty of Industry 4.0 projects that were profligate with finite resources or so brittlely designed that they collapsed in the face of external pressures. Those projects weren’t bad because Industry 4.0 is bad. They were just bad projects. They deserved to fail, and they did. There’s nothing about Industry 4.0’s approach to people, planet, or process that requires a revolution to put right.

Just Do Industry 4.0 Properly

Industry 5.0, as currently defined, makes no sense and brings no value. It’s a marketing gimmick from people and organisations that should know better. It devalues every single “revolution” that preceded it, and does a disservice to all the companies doing Industry 4.0 carefully, thoughtfully, and well. Let’s agree to stop using the Industry 5.0 term and save it for something truly transformative: clean, sustainable, autonomous, safe, nonpolluting, and affordable mass manufacturing in orbit, maybe? Then we can get back to sharing today’s good practice, to ensure that every Industry 4.0 initiative is “sustainable, human-centric, and resilient.” No number inflation required!