Manufacturers Use Emerging Technologies To Find A Mix Of Factory Locations That Is Just Right

In the eponymous fairy story, Goldilocks was a little girl in search of perfection. The porridge she stole from unsuspecting bears shouldn’t be too hot or too cold, but just right. Their chairs and beds shouldn’t be too hard or too soft for her, but just right. Her search for perfection inspired the latest collaboration between my colleague George Lawrie and myself, and our new report — Goldilocks Manufacturing Is Neither Just In Time Nor Just In Case, But Just Right — has just been published.

In the eponymous fairy story, Goldilocks was a little girl in search of perfection. The porridge she stole from unsuspecting bears shouldn’t be too hot or too cold, but just right. Their chairs and beds shouldn’t be too hard or too soft for her, but just right. Her search for perfection inspired the latest collaboration between my colleague George Lawrie and myself, and our new report — Goldilocks Manufacturing Is Neither Just In Time Nor Just In Case, But Just Right — has just been published.

The story of where manufacturing gets done in the world is often reduced to almost fairy tale-like simplicity itself. This digestible narrative explains how, once upon a time, manufacturing moved “offshore,” to faraway places that were low-cost and efficient. Fast-forward a decade or two, and the story becomes one of “reshoring,” with politicians of many parties and nationalities trumpeting the value of bringing jobs home from countries that are no longer as affordable or as politically acceptable as they once were.

This simple story makes a lot of sense when you hear it, and it contains a grain or two of truth, but it misses so much nuance that it’s essentially worthless for any serious consideration of manufacturing and its supply networks.

Yes, manufacturers offshored production. But they still do: European chemical giant BASF’s third-largest global facility will soon be operational in China’s Guangdong province. Yes, manufacturers are investing in their home countries. But they never really stopped doing that: Almost 20% of Volkswagen Group’s cars were built in Germany in 2022.

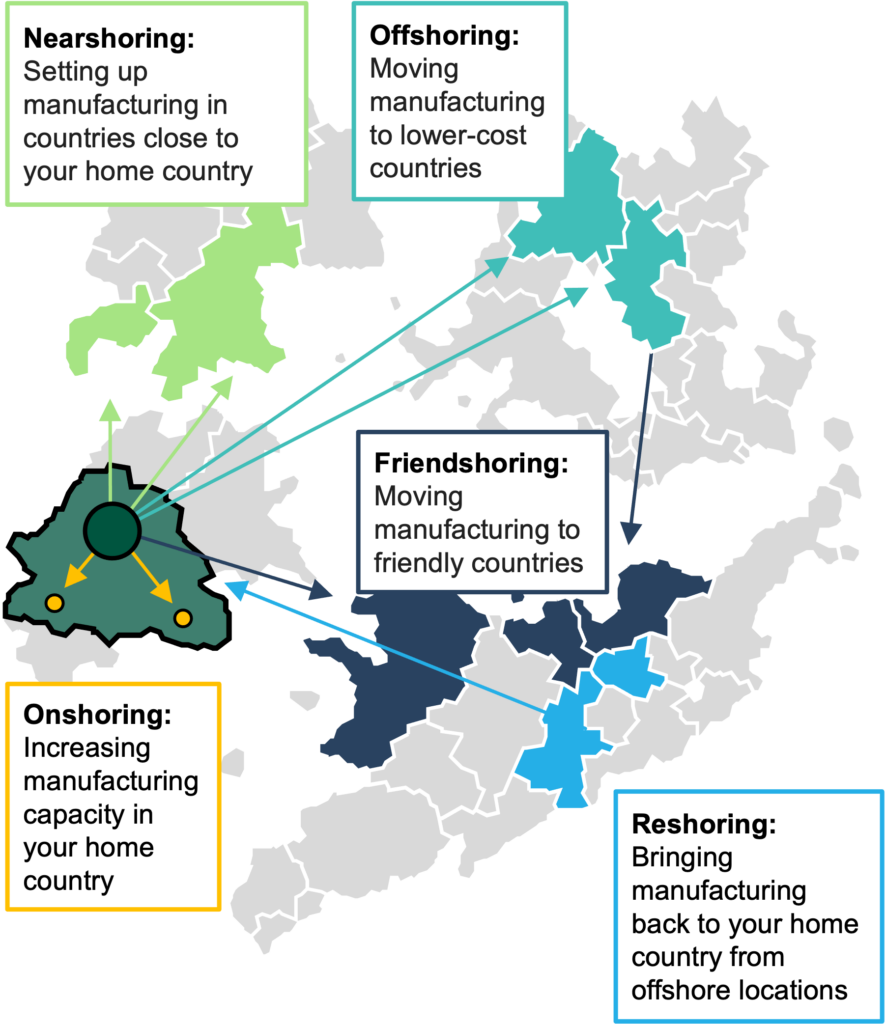

Few companies, if any, can adopt a single model for their global manufacturing operations. The neat fairy story simply doesn’t work. The world is messy and complicated, and as we discuss in the report, manufacturers must find their own combination of offshore, onshore, nearshore, reshore, and friendshore models.

We (and others) call each manufacturer’s “just right” mix of the options rightshoring, but then we discuss how emerging technologies such as ubiquitous sensing, distributed computing, AI and machine learning, additive manufacturing, flexible microfactories, and data fabrics for connected intelligence can be used to change the calculation about what gets made where and when.

As always, if you have your own perspectives to share, please schedule a briefing and tell us all about them. If you’re a Forrester client and want to discuss (or challenge) our thinking on this topic, please schedule an inquiry.

(Out-of-copyright image of Goldilocks eating porridge from the 1908 publication, “Cinderella, or, The little glass slipper,” digitized by the Internet Archive and available at Wikimedia Commons; map of manufacturing locations from the Forrester report, Goldilocks Manufacturing Is Neither Just In Time Nor Just In Case, But Just Right)